Your cart is currently empty.

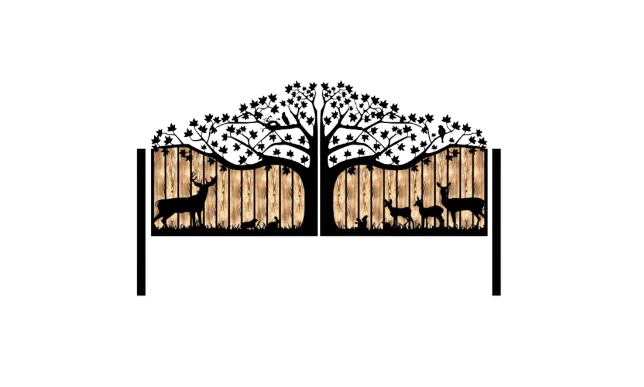

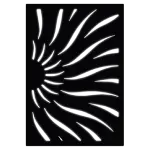

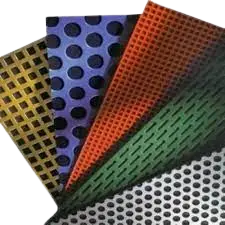

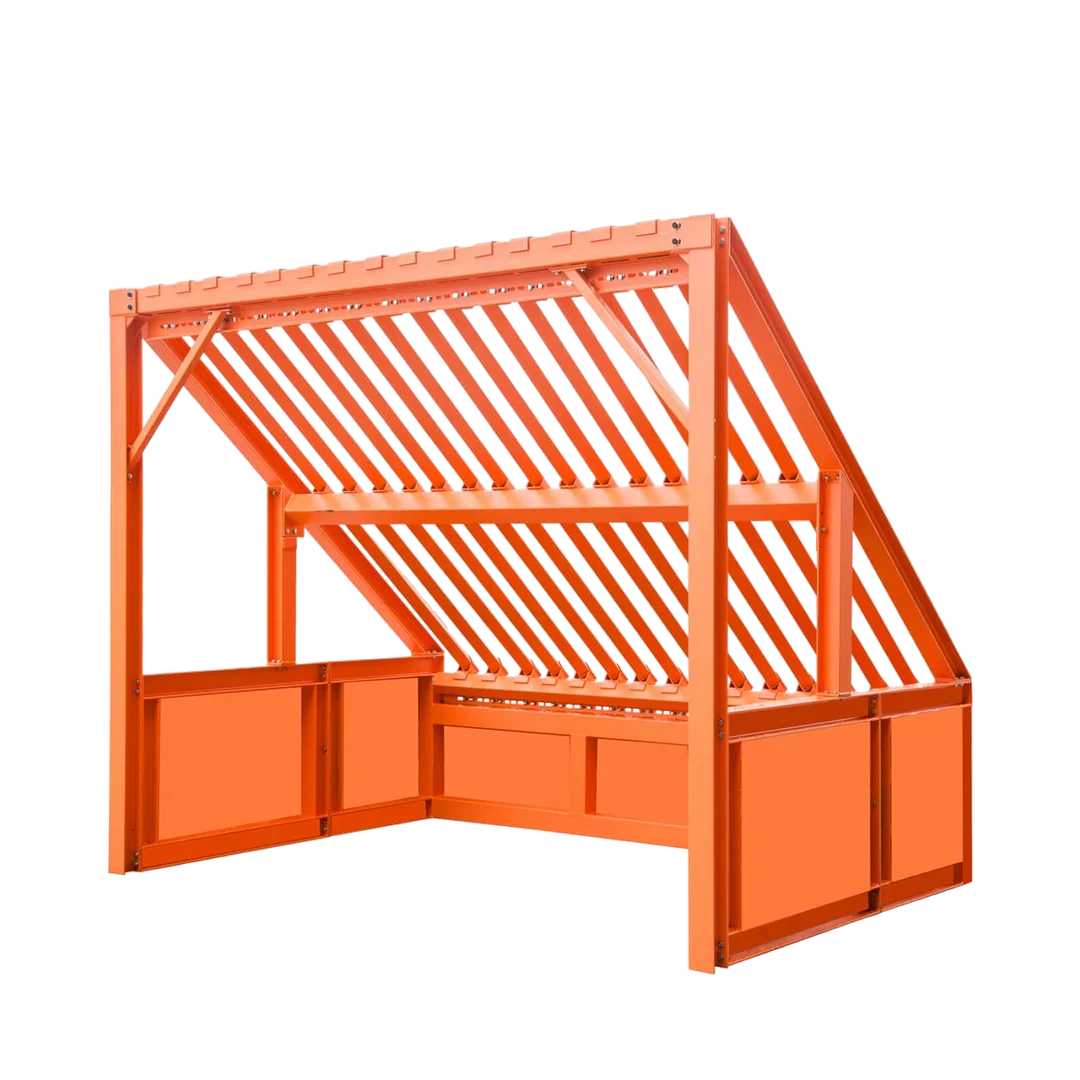

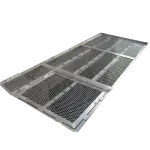

Metal Panels Powder Coating Model MPPC2209

Free Delivery

US & Canada

-

Powder Coating Basics:

- Powder coating is a dry finishing process where a fine powder is applied electrostatically to a metal surface. The coated part is then cured in an oven, resulting in a durable and attractive finish.

- It offers advantages such as excellent corrosion resistance, colour variety, and environmental friendliness.

-

Surface Preparation:

- Proper surface preparation is crucial for successful powder coating.

- Cleaning: Remove dirt, grease, and contaminants from the metal surface using solvents or alkaline cleaners.

- Degreasing: Ensure the surface is free of oils and grease.

- Etching: For aluminum, use an etching solution to improve adhesion.

-

Application Process:

- Electrostatic Application: The powder is sprayed onto the metal surface using an electrostatic gun. The charged particles adhere to the grounded metal.

- Uniform Coating: Achieve an even coating thickness by adjusting the gun settings and ensuring consistent coverage.

-

Curing:

- After application, the coated metal is heated in an oven to cure the powder.

- Temperature: Typically, curing temperatures range from 300°F to 450°F (149°C to 232°C).

- Time: The curing time depends on the specific powder coating material.

-

Powder Coating Materials:

- Different types of powder coatings are available:

- Epoxy: Good adhesion and chemical resistance.

- Polyester: Offers UV resistance and colour retention.

- Polyurethane: Provides excellent durability and weather resistance.

- Hybrid: Combines properties of epoxy and polyester.

- Different types of powder coatings are available:

-

Quality Standards and Testing:

- ASTM Standards: ASTM B117 (Salt Spray Test), ASTM D7091 (Dry Film Thickness Measurement), and ASTM D1654 (Corrosion Evaluation) are relevant.

- AAMA Specifications: AAMA 2603, 2604, and 2605 define performance requirements for architectural coatings.

-

Environmental Considerations:

- Powder coating is environmentally friendly due to minimal volatile organic compounds (VOCs) and no hazardous air pollutants.

- Proper disposal of overspray and waste powder is essential.

- Industrial powder coating is a surface treatment used to protect metals and other materials against potentially harmful environmental factors.

- This coating is applied electrostatically as a free-flowing powder and cured under heat or UV light.

- It can provide a durable and long-lasting finish that resists marring, weathering, corrosion, and abrasion.

- We have over 23 years of experience in the industry and we offer competitive pricing across North America.

- We can produce thousands of linear feet per shift and we have solutions for faster results and efficient processes.

- Powder coating has many advantages over conventional liquid paint, such as:

When it comes to powder coating for metal panels and sheets, there are several important technical and engineering aspects to consider :

Key Points:

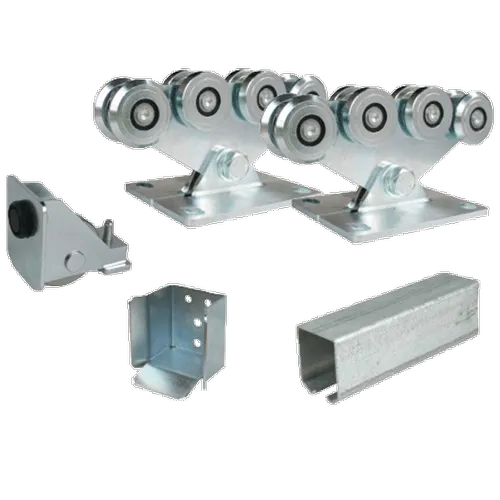

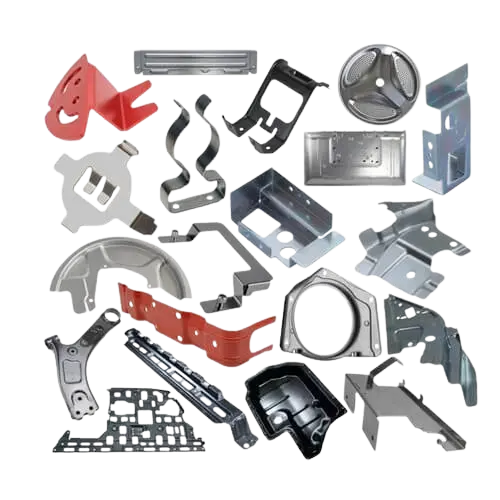

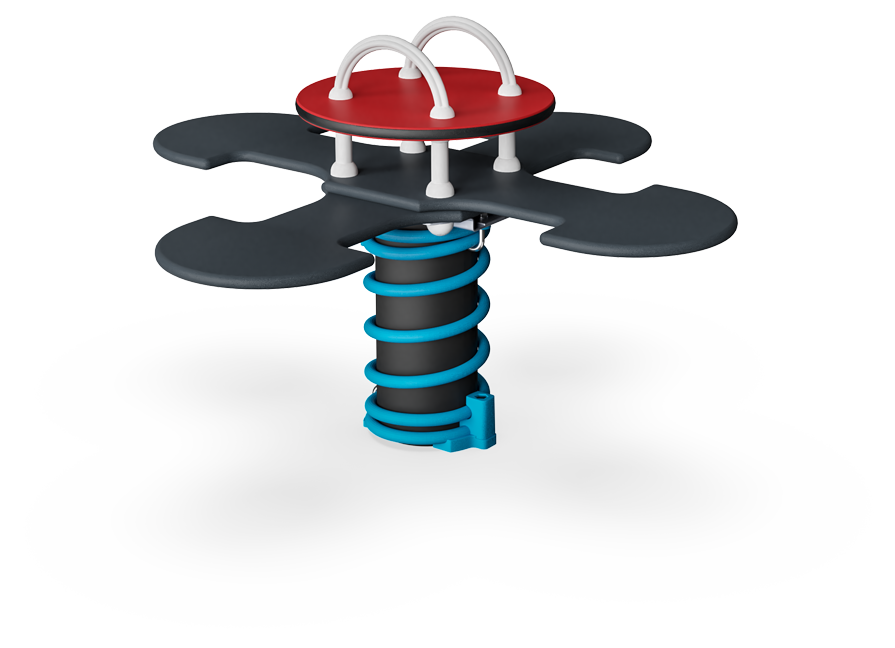

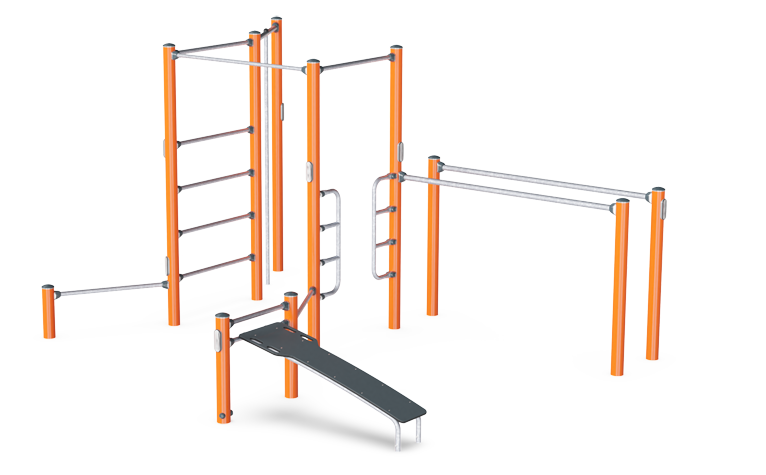

We can powder coat various types of products, such as:

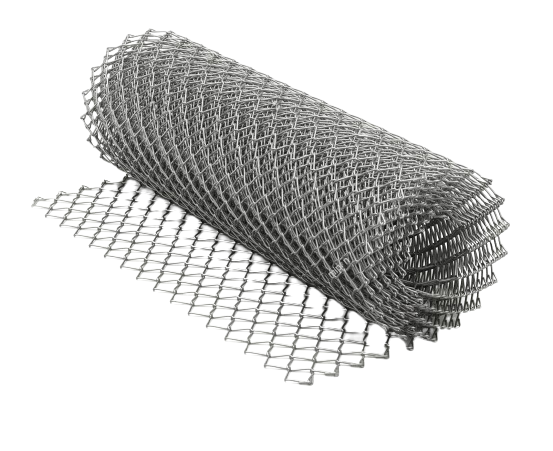

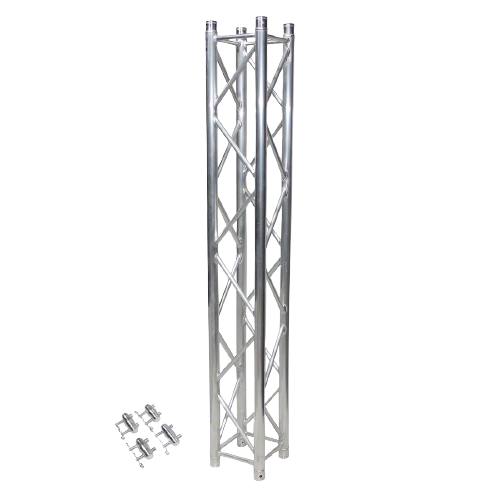

1 - Metal fencing and railings.

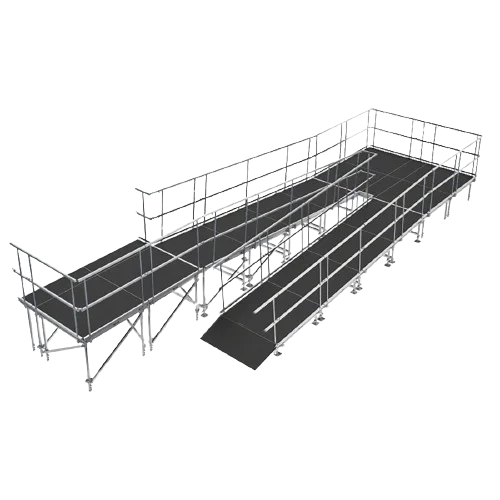

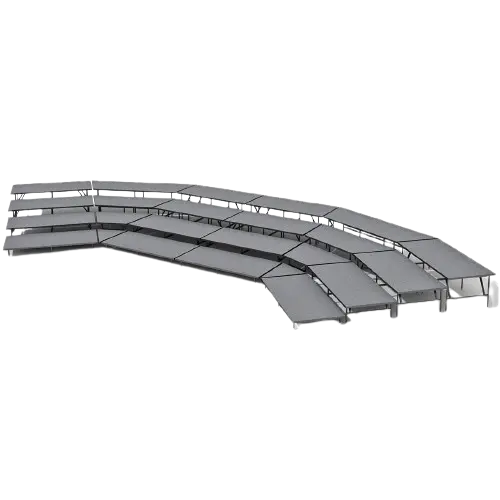

2 - Industrial fabrications.

3 - Retail display units.

4 - Retail fixtures.

Contact us today to get a quote or to learn more about our industrial powder coating services. We are ready to help you turn your big ideas into great products.

The prices listed are for black Colour, please Contact us for a quotation on custom colors.

Email: info@taimco.ca

Get a quote in 24 hours!