Your cart is currently empty.

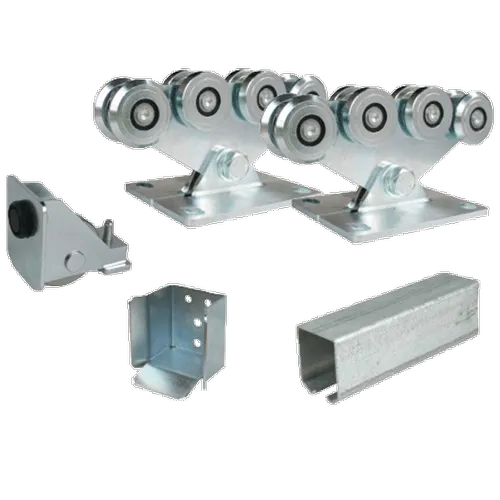

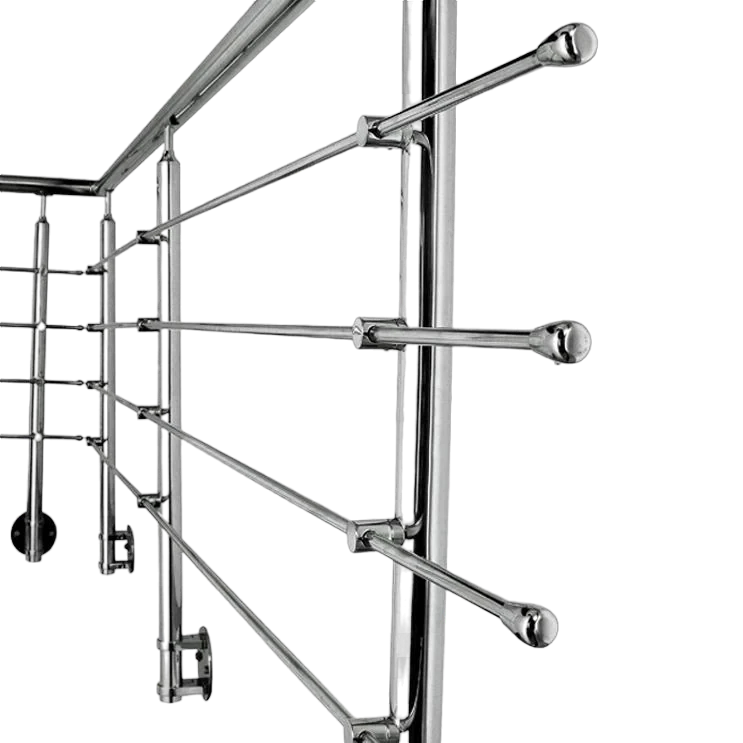

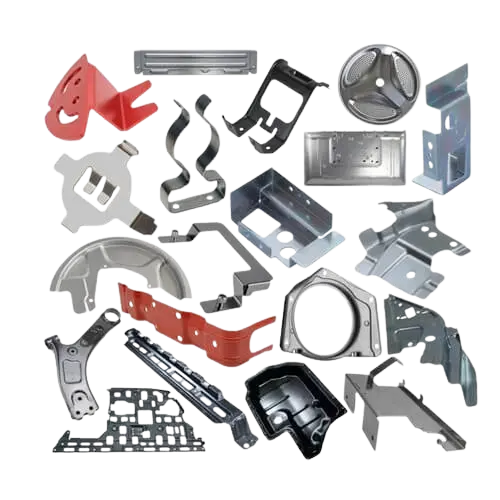

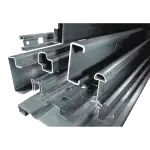

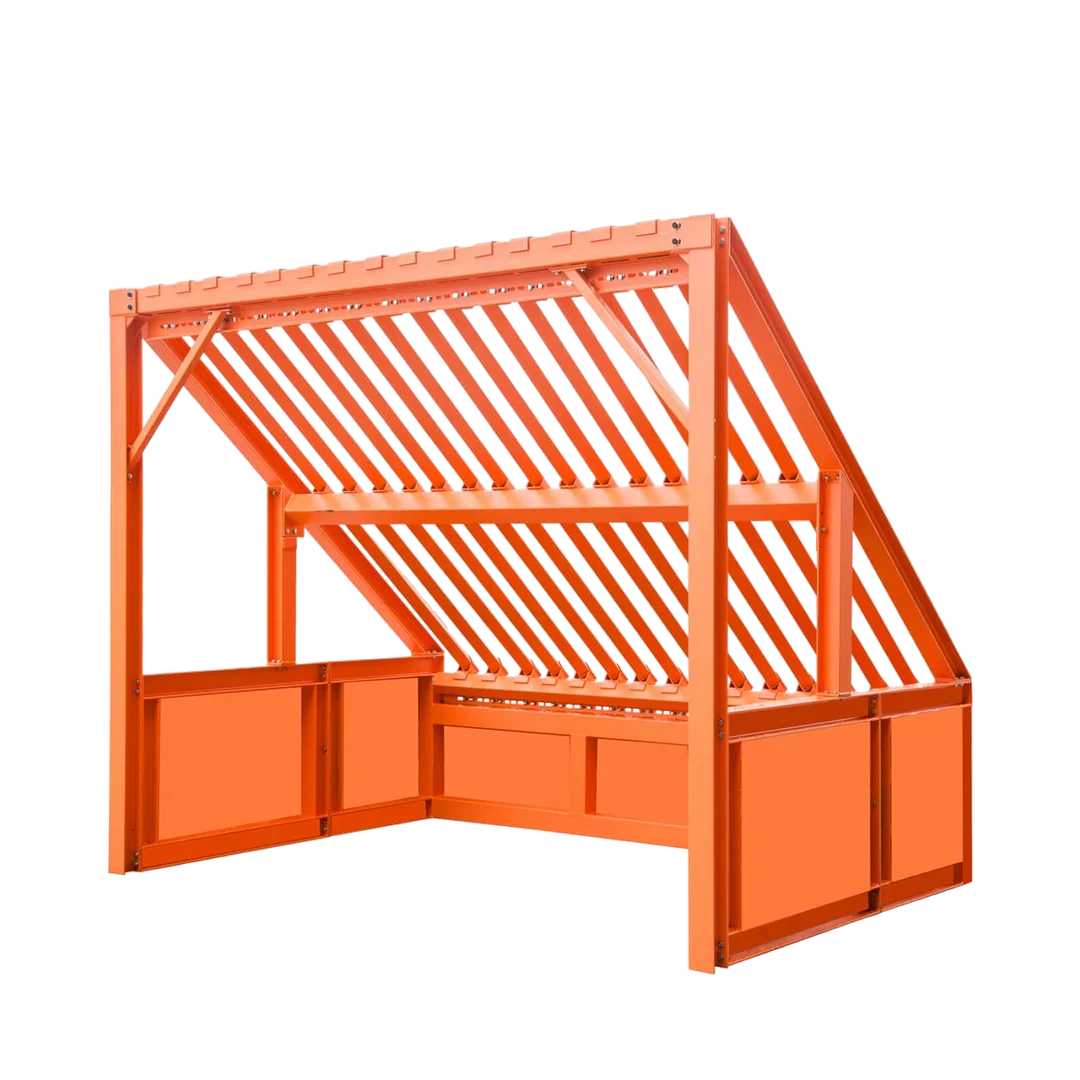

Metal Parts Powder Coating Model MPPC2285

- Custom powder coating gives parts a bold, long-lasting finish and protective layer which provides corrosion, oxidation, and damage resistance.

-

Durable and aesthetic, powder coating is one of the best finishing processes for Metsl parts.

-

What Is Powder Coating?

-

How Does Powder Coating Work?

- Ingredients: Powder coating consists of a mixture of polymer resin, flow modifiers, levelling agents, and other additives.

-

Process:

- These ingredients are melted, mixed, cooled, and then ground into powder.

- An electrostatic paint sprayer is used for application.

- The powder is given a positive electrical charge and adheres to the metal parts.

- The result is a durable and visually appealing finish.

-

Types of Metal Finishing Techniques:

- Electroplating: This technique uses chemicals and an electric current to adhere to a thin layer of metal over the product.

- Powder Coating: Unlike electroplating, powder coating uses UV or heat curing to form a layer of plastic powder over the surface.

- Other common metal finishing processes include brushing, polishing, grinding, blasting, vibratory finishing, and heat-treating.

- Recent innovations in metal finishing have made these techniques more effective, affordable, and sustainable.

-

Advantages of Powder Coating:

- Durability: Powder-coated surfaces are highly resistant to heat, chemicals, corrosion, and impact.

- Aesthetics: The process enhances the appearance of metal parts.

- Environmental Benefits: Powder coating is more environmentally friendly than traditional wet painting due to reduced waste and emissions.

- Uniform Coating: The electrostatic process ensures an even application of the powder.

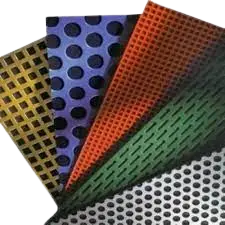

- Wide Range of Colors: Powder coating offers a variety of colour options.

-

Innovations in Metal Finishing:

- Hydrophobic and Hydrophilic Prepainted Metal: Applying even paint layers before fabrication results in a more even and durable finish.

- Advances in Sustainability: Innovations are making metal finishing more sustainable and cost-effective.

- Increased Demand: As consumers and corporations seek higher quality and performance from materials, metal finishing practices continue to evolve.

- Send us your parts file for Quotation to info@taimco.ca, file formats can be ( .dxf - .dwg - .ai - .eps - .stp ).

- if you do not have the file we can help you build the part-cutting drawings file through the drawing design service we provide, Send us a sketch or template, and we'll help you convert it to a part.

- Custom Quote for projects including unique needs or requirements, we can provide a custom quote, Request Quote.

-

Starting From $20, no Minimum Quantity, As low as $2.50 per part in bulk!

In the dynamic landscape of rapid prototyping, powder coating stands out as a versatile finishing technique. Beyond mere aesthetics, it plays a pivotal role in enhancing the durability and performance of meticulously crafted machine parts.

Material Available for powder coating:

Materials intended for powder coating must meet specific criteria: they must be capable of retaining an electrostatic charge and withstanding elevated curing temperatures. As a result of these prerequisites, aluminum, mild steel, and stainless steel emerge as the optimal choices for powder coating. Moreover, we have the flexibility to apply powder coating to these materials at various thickness levels.

| Material | Thickness |

| 5052 Aluminum | 0.063" - 0.55" |

| 6061 Aluminum | 0.063" - 0.55" |

| 7075 Aluminum | 0.125" - 0.25" |

| Mild Steel | 0.048" - 0.5" |

| G30 Galv Steel | 0.036" - 0.059" |

| G90 Galv Steel | 0.03" - 0.047" |

| 4130 Chromoly Steel | 0.05" - 0.25" |

| 304 Stainless Steel | 0.048" - 0.5" |

| 316 Stainless Steel | 0.06"- 0.25" |

How to Order Your Powder Coating Parts?

Contact Us Today To Get a Quote to learn more about our powder coating Complete services.

Email: info@taimco.ca

Get a quote in 24 hours!